HYDRAULIC REPAIR & MANUFACTURING

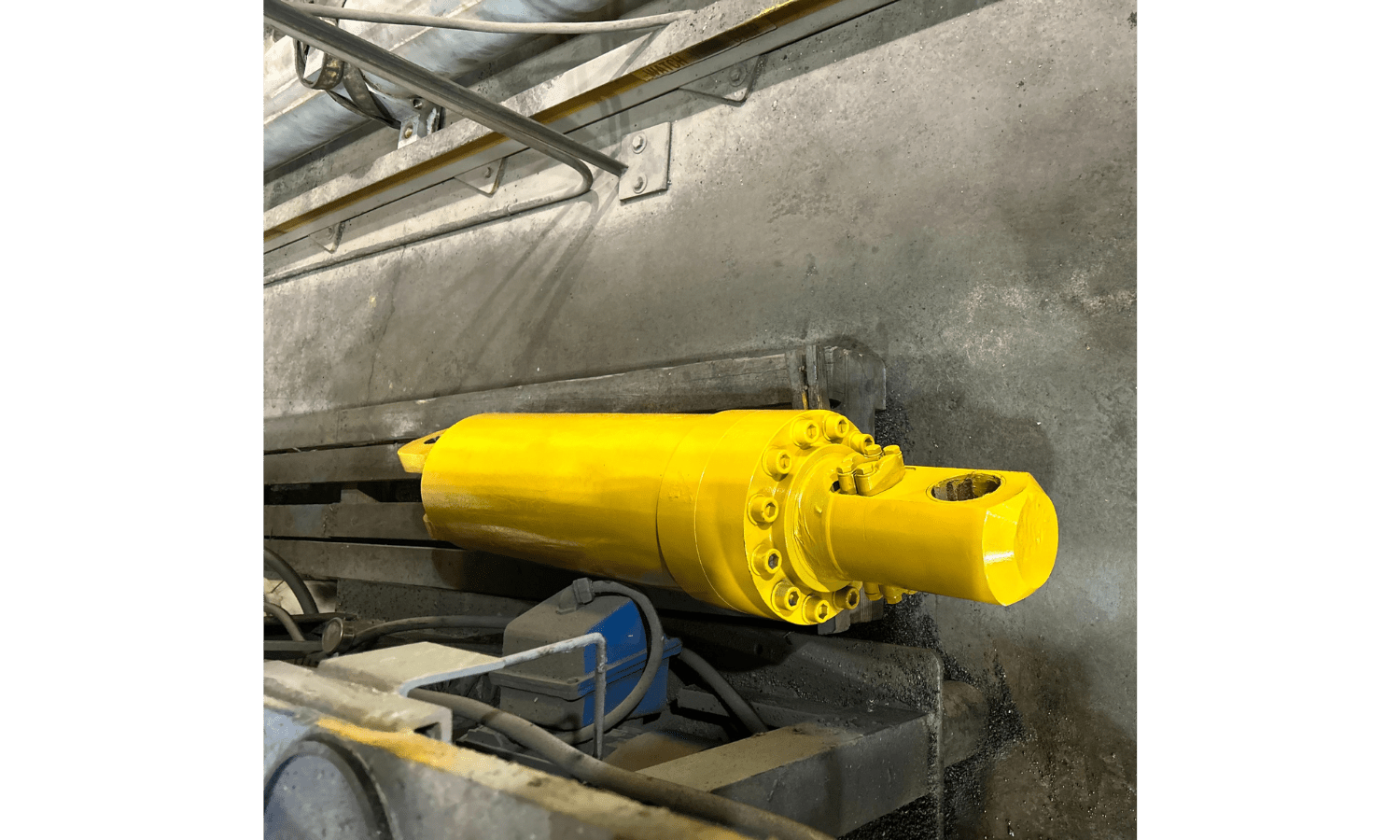

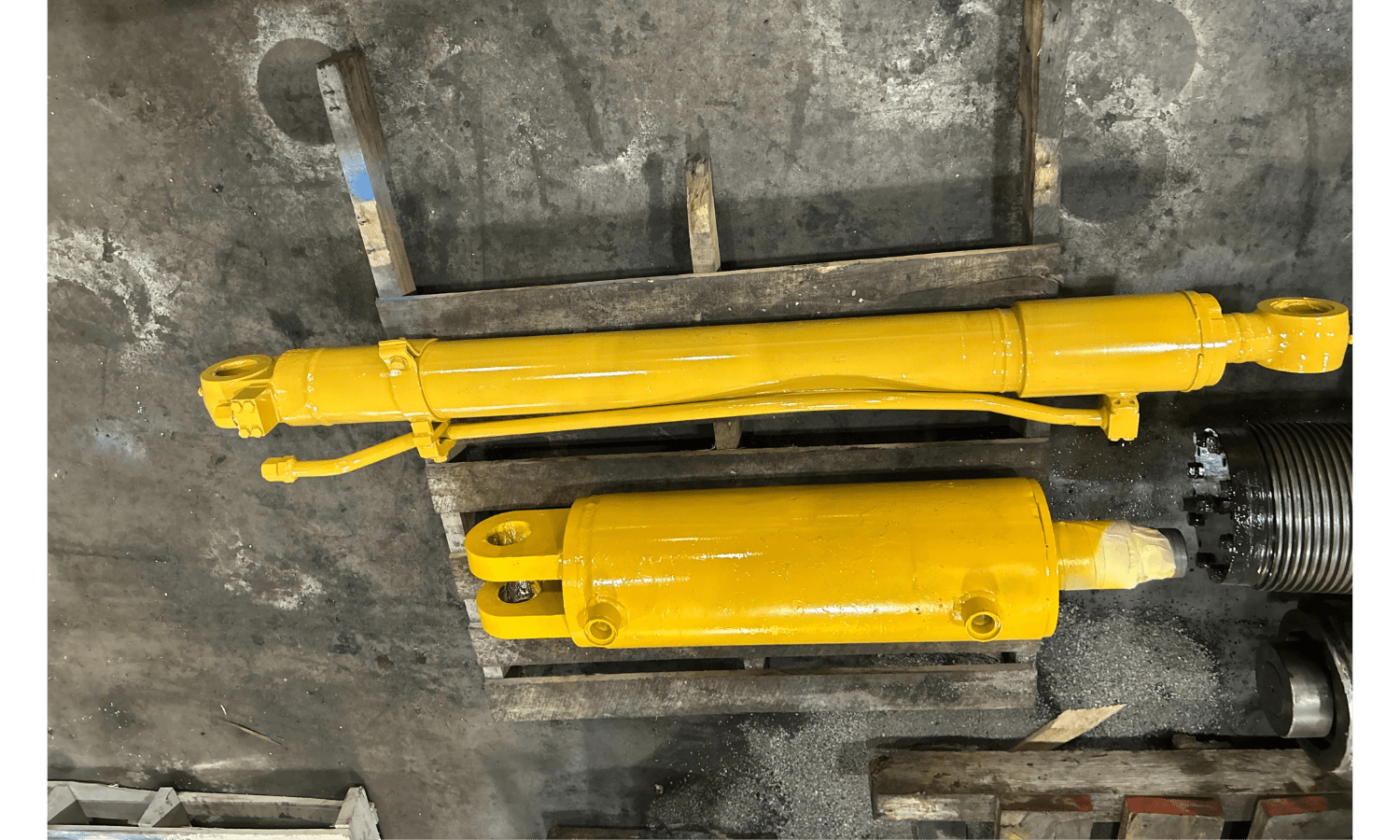

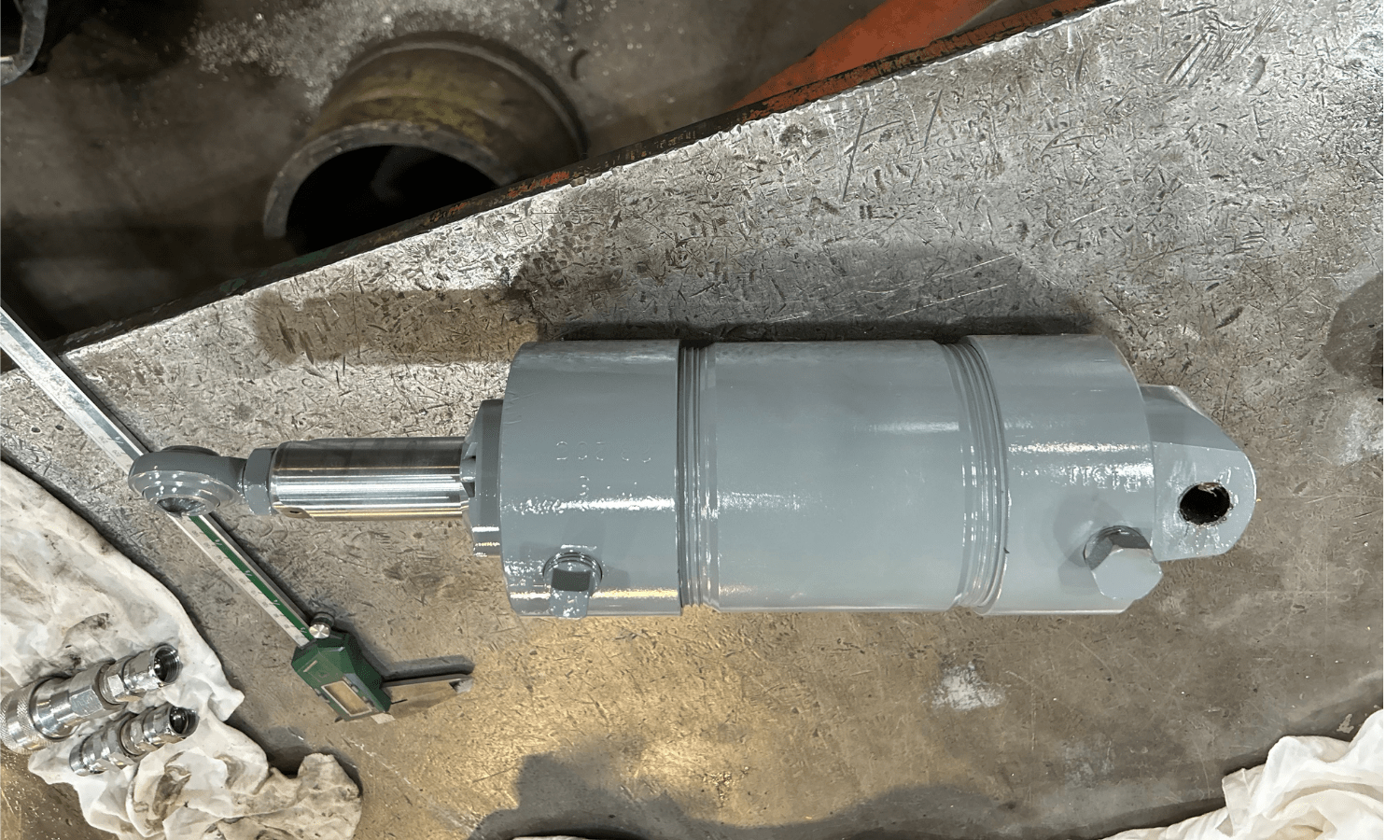

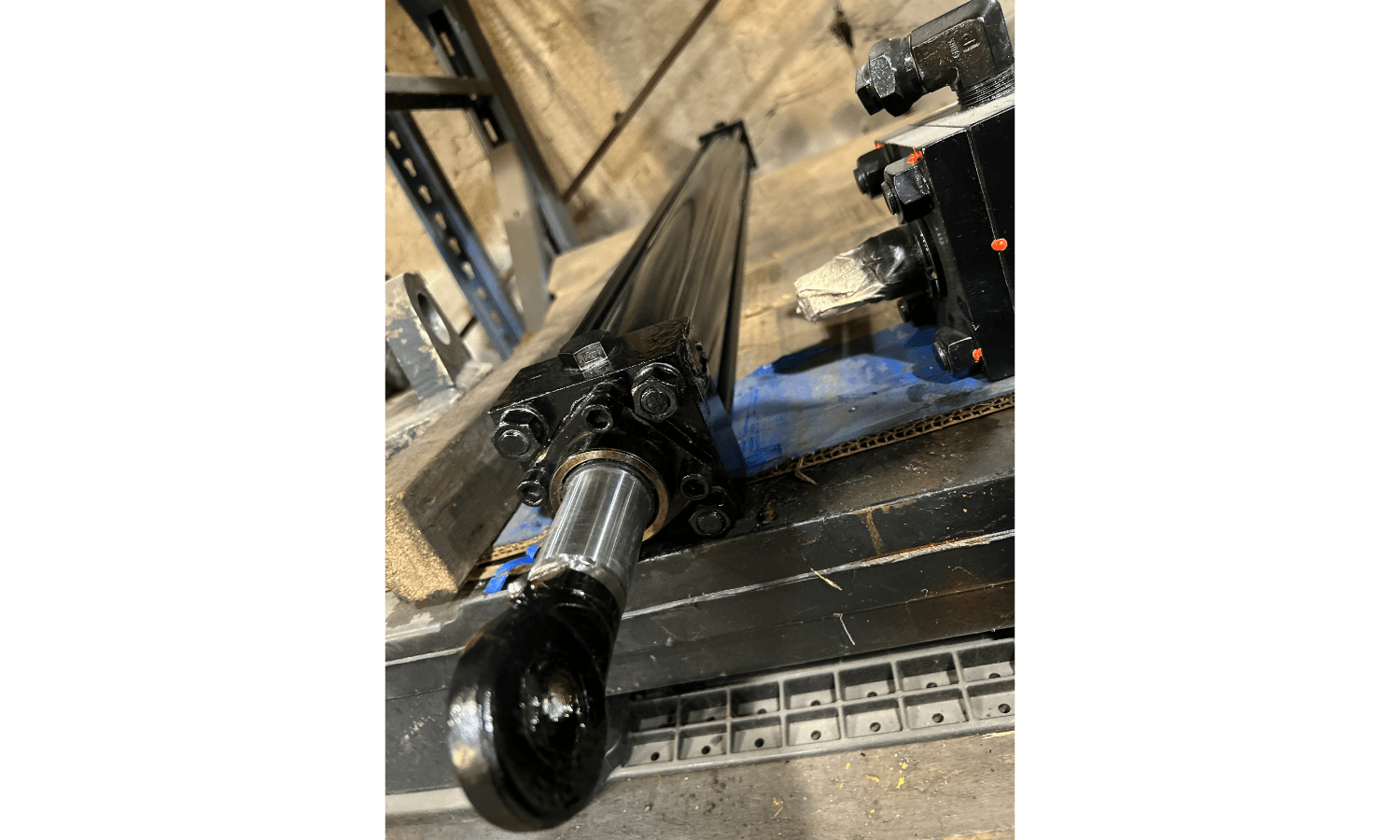

Cylinder Repair

Our Services

Cylinder Repair

- Disassemble, Inspect & Advise

- Damage Assessment & Repair Plan

- Machining, Honing & Component Repair

- Reassemble & Final Testing

- 24-month Warranty

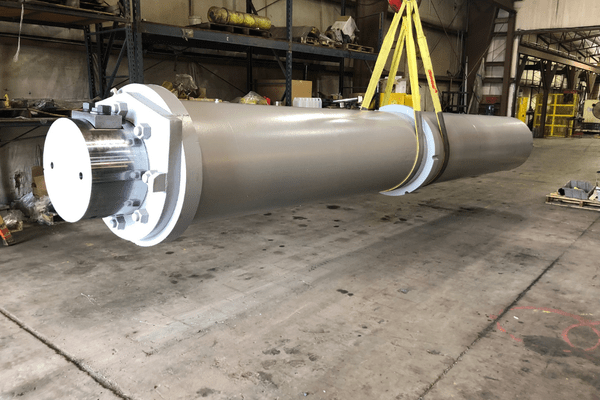

Custom Cylinder Manufacturing

- Build Cylinder to OEM Specs or Application Requirements

- Design for required bore, stroke, pressure and mounting style.

- Manufacture welded tube, tie-rod anf mill-duty designs

- Provide Interchangeability with exisiting customer equipment

- Documentation support: drawings, BOMs, and build records

Hydraulic System Service & Repair

- Repair Pump, motor, and valve inspection

- Hydraulic Power Unit (HPU) service, rebuild and upgrades

- Filtration inspection, upgrades and contaminiation control

- System flushing and fluid condition evaluation

- On-stie support and shutdown assistance

OEM & Reversed Engineered Cylinders

- Reverse-engineer discontinued or hard-to-source cylinders

- Imporve known weak points with upgraded materials/components

- Provide interchangeability for fleet standardization

- Create updated drawings for future builds

- Support legacy equipment in harsh environments

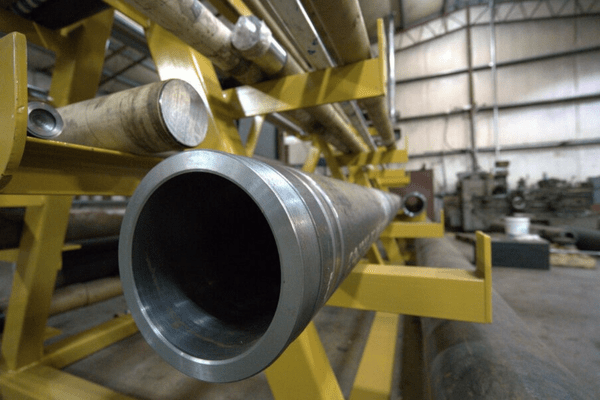

Capabilities & Specifications

Facility & Capacity

- Bore Diameters up to (?) Inches

- Stoke lengths up to (?) Inches

- Operating pressures up to (?) PSI

- Single-acting and double-acting cylinders

- Small-bore to heavy mill-duty designs

Materials & Finishes

- Chrome-plated, induction-hardened, and specialty-coated rods

- Carbon Steel, alloy steel, and stainless steel options

- Sandblasting and OEM painting

- OEM Seal Kits

- Honed tubing to OEM Specifications

Quality System

- ISO 9001 Certified

- Standardized Inspection Template

- Inspection of rod straightness, bore conidition and visual weld check

- Pressure and functional testing completed prior to shipping

- Documented final inspection upon request

Equipment & Facility Photos

PHONE

(844) 426-8971

KENTUCKY FACILITY

8379 S.R. 168 Catlettsburg, ky 41129 606-739-8680